PGS and Cognite have systemized data to increase PGS vessel speed without jeopardizing the seismic acquisition operation or the vessel integrity.

PGS said it was using Industrial DataOps provided by Cognite, including Cognite Data Fusion™, to give seismic vessel operators a clear overview of the factors determining a vessel’s optimal operating speed. The solution cuts production time for PGS current fleet by more than 15 days, saves the company more than $2 million a year and reduces manual reporting by approximately one month.

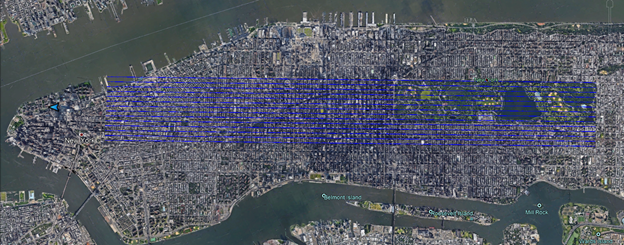

A PGS Ramform vessel with a full streamer spread deployed is among the world’s largest moving objects. Steering the vessel through waves and currents while at the same time allowing for sufficient recording of the seismic data means there are several different factors restricting the production speeds.

Through its vessel digitalization initiative, PGS Proteus, PGS aims to increase operational efficiency by using and combining available data. In this specific case, PGS saw an opportunity to combine the factors that influence a vessel’s optimal operating speed into a single easily accessible tool. This would provide transparency and the ability to identify which factors have the largest impact on the production speed.

A vessel speed optimization tool would also enable PGS to optimize seismic surveying in real time and improve on, or even remove, speed restricting factors, helping the company reduce costs while maintaining a high level of quality.

“There is a strong link between acquisition speed, efficiency and value creation. For the project planning and bidding process, it is of great importance to know the potential for daily revenue, as well as the planned duration for a survey. With better tools in place to document historical achievements, better, data-driven decisions can be made more quickly,” PGS said.

PGS and Cognite worked together to streamline data ingestion pipelines between Cognite Data Fusion™ and the systems containing data relevant to calculate the optimal speed of seismic vessels.

Using the Cognite Power BI connector and self-service training provided by Cognite Academy, PGS’ subject-matter experts developed Power BI reports combining vessel sensor and operational data. These reports have given unprecedented insight into the details of vessel production performance. The dashboards are used in onshore project planning, and the Company is working toward making the information more available to the vessels as well.

PGS’ subject-matter experts have also developed an onboard vessel speed dashboard, building and iterating with vessel crews to create the best visualizations for their use. The dashboard combines data from the most relevant systems representing the various restricting factors. The different inputs are transformed and presented to the vessel crews, indicating whether a further speed increase is recommended. The speed related data is automatically transmitted to shore, for ingestion into Cognite Data Fusion™.

PGS vessel crews have for years been monitoring and pushing production speed upwards. Particularly the powerful Ramform Titan-class vessels have shown their potential for speed increase. With the vessel dashboard in place, the crews’ job has become easier, removing parts of the manual process and supporting decision-making. The input data for further analysis has also improved in consistency.

While achieved speed varies between surveys, PGS has seen a marked improvement in the maximum acquisition speeds since implementing the vessel speed dashboard. In the fall of 2020, PGS’ three fastest surveys showed an average speed increase of 5.5% compared with the three fastest surveys in 2019.

PGS is now in a better position to make further improvements, moving towards machine learning and automated speed control. One of the company’s main focuses for 2021 is to work reliably at level four on the 10-point Sheridan-Verplank scale of automation, where the computer suggests optimal bottom speed. Once this is in place, PGS aims to reach level seven, where the computer executes the speed control and reports to the crew.