Shell’s Deepwater Project Delivery Digital Platform for the Gulf of Mexico and OQ’s asset performance optimization of pipelines in Oman have emerged as finalists in this year’s Bentley Going Digital Awards in Infrastructure event.

The annual awards ceremony features many of the world’s most spectacular infrastructure projects. Two previous special awards winners in the hydrocarbon sector were the Gorgon Project in Australia and Shell’s Pearl LNG Project in Qatar.

This year Shell’s Deepwater Project and OQ’s Oman operation were two of the three finalists in the Process and Power Generation categories. The third finalist was Sarawak Energy Berhad’s modernisation of the Bakun Hydroelectric Plant With a Digital Twin in Malaysia.

Winners in the Going Digital Awards in Infrastructure are determined after deliberation by an independent panel of jurors. Using criteria specific to each category finalists must demonstrate excellence and digital advancements in their respective awards category

The citations for the Shell and OQ’s projects were as follows:

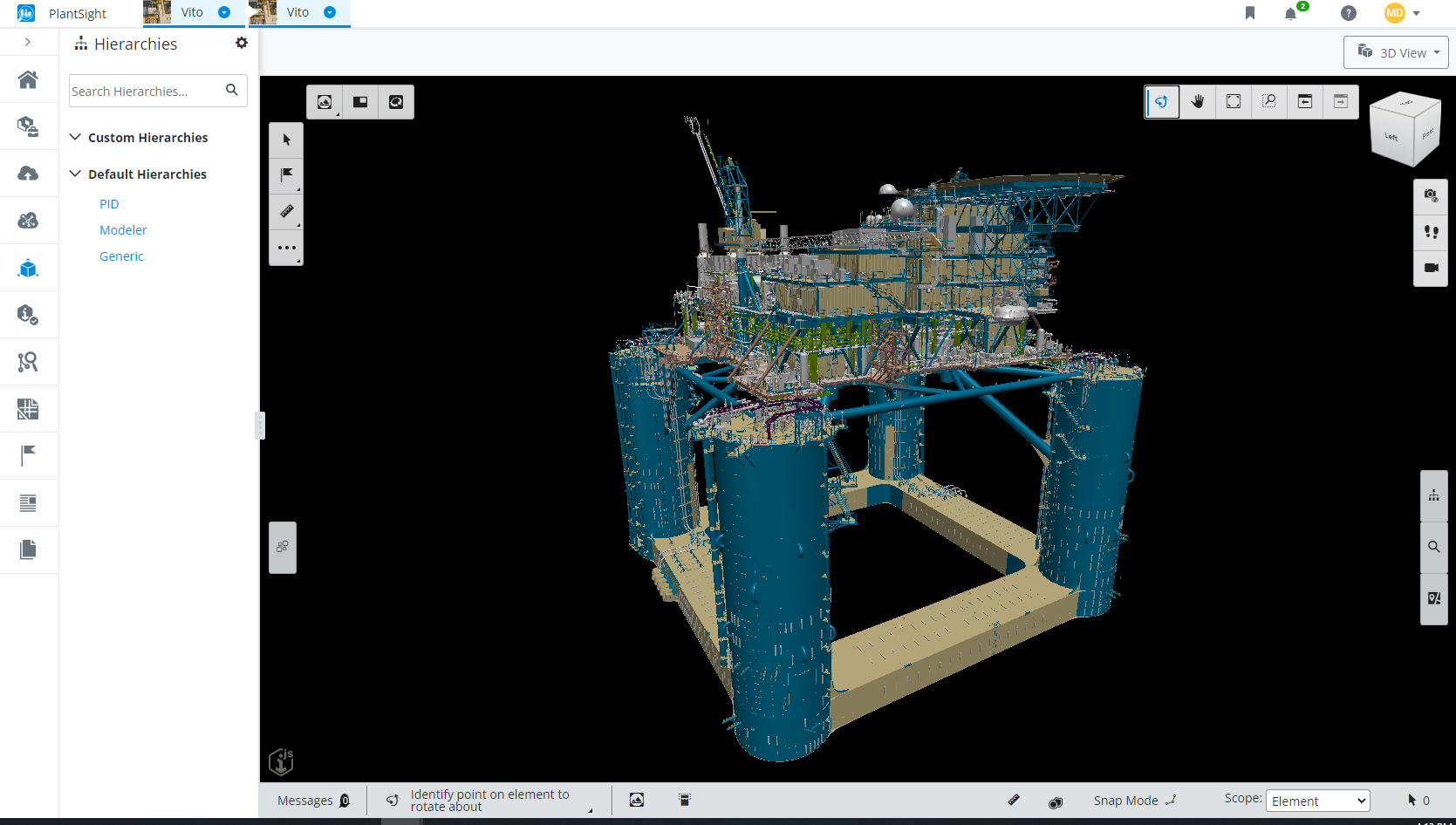

Shell Deepwater Project Delivery Digital Platform, Houston, Texas

Project Playbook: AssetWise, iTwin, iTwin.js, Orbit, PlantSight, SYNCHRO

Shell identified a portfolio of projects in the Gulf of Mexico to deploy an integrated project delivery digital platform, continuing top cost performance while also working toward meeting net-zero carbon goals and further improving project cycle times for deep water projects. This end-to-end digitization from concept design, to handover, to operations presented challenges, including integrating multi-sourced data. To achieve their goal, Shell needed open, interoperable technology applications.

Leveraging, amongst others, PlantSight and AssetWise ALIM, Shell developed a digital platform that provides a single source of truth from project conception through delivery of a digital twin for operations and beyond. Working in an integrated digital environment optimizes data access, visualization, and remote collaboration, improving efficiencies, reducing time for project teams to find information by 50%, and eliminating work duplication. By digitizing workflow orchestration and supporting end-to-end project delivery, Shell expects to see significant productivity gains and cost savings. The PlantSight digital twin solution can be scaled as projects expand or new ones arise.

OQ Asset Reliability Digitalization With Purpose, Oman.

Project Playbook: AssetWise

OQ, an integrated energy company, operates and manages dozens of plants, thousands of assets, and over 4,500km of pipeline across Oman. To improve asset performance and reliability and ensure safe and reliable plant operations, OQ wanted to digitalize asset management processes. Scattered paper asset data records and previous reactive maintenance methods proved costly and ineffective. OQ realized that they needed to establish a centralized digital asset performance management (APM) system.

They selected AssetWise as their central asset data management platform, incorporating failure reporting and analysis, asset health indicators, and digital inspection strategies to enable corrective maintenance management. Their digitalized APM system reduced asset failures and unplanned plant shutdowns, minimizing environmental risks of flaring. Based on APM implementation at one compressor site, the digital solution saved 14.8% in total maintenance costs and reduced functional failures by 50% to achieve an annual operational reliability growth of 4.3%. Continuing to digitize, OQ is integrating APM as part of their efforts to develop a digital twin.